Hongkong NKF Machinery Co., Limited. is a major distributor of bearing products with a global presence, serving customers in different industries. We offer a comprehensive range of products, from standard bearings to custom solutions, all from reputable manufacturers. Our team of expert engineers and technicians are well-equipped to provide technical support and assist customers in selecting the right bearings for their applications.

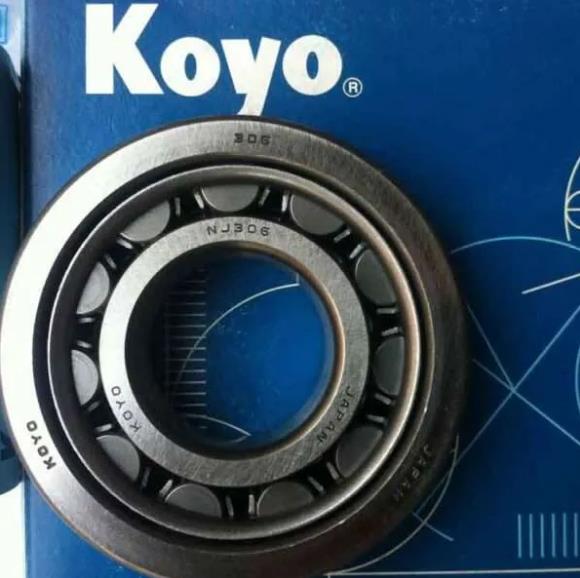

Bearing is a crucial component in many machines and equipment, providing smooth and efficient rotary motion. It is a circular device that supports and reduces friction between moving parts, allowing them to rotate freely. With a wide range of applications, bearings are used in industries such as automotive, aerospace, and industrial machinery. Our bearing products are designed with high precision and quality materials, ensuring reliability and durability. We offer various types of bearings, including ball bearings, roller bearings, and needle bearings, to suit different needs and operating conditions. Our bearings are capable of handling heavy loads, high speeds, and extreme temperatures, making them suitable for various demanding environments. In addition to standard bearings, we also provide customized solutions to meet specific requirements. Our team of experts works closely with customers to understand their application and design bearings accordingly. With advanced manufacturing technologies and rigorous quality control processes, our bearings are known for their superior performance and long service life. Choose our bearing products for your machines and equipment, and experience smoother and more efficient operations. With ourcommitment to quality and customer satisfaction, we strive to provide the best bearing solutions for all your needs.

about cross roller bearing , we have carefully prepared some relevant professional knowledge documents for you. We hope to provide some help to you who have related product needs for transmission bearing .

The Superior Strength of Our Bearing Products

1NKF tested and trusted transmission bearing designs have proven to be durable and reliable, standing the test of time. Through rigorous testing and continuous improvement, these designs have withstood the harshest conditions and have remained in top condition for extended periods of time. The longevity of our bearings is a testament to the quality and precision of our engineering and manufacturing processes. With these designs, our customers can have peace of mind knowing that their machinery and equipment will continue to function smoothly and efficiently for years to come. Our commitment to providing long-lasting and dependable bearing designs has made us a preferred choice for numerous industries worldwide. Trust in our bearings and experience the longevity and performance that we are known for.

2NKF transmission bearing are renowned for their unmatched accuracy, making them an essential component in a wide range of industrial and mechanical applications. With precise manufacturing techniques and strict quality control measures, our bearings offer unparalleled levels of precision, ensuring smooth and efficient operation in any environment. Whether it's in heavy-duty machinery, automotive systems, or delicate equipment, our bearings provide reliable and consistent performance, making them a trusted choice for engineers and manufacturers worldwide. Trust in our bearings for unparalleled accuracy and superior reliability.

With years of experience and expertise, our bearings have become the top choice for demanding applications. Our bearings are specifically designed and engineered to withstand heavy loads, high speeds, and harsh environments, making them suitable for a wide range of industries including automotive, aerospace, and industrial manufacturing.One of the main reasons our bearings stand out is their superior quality. We only use the best materials and employ the latest manufacturing techniques to ensure unmatched durability and reliability. This not only results in longer product life but also minimizes maintenance and replacement costs.

At NKF, we pride ourselves on our advanced bearing technology that is paving the way for industry advancements. Our innovative designs and cutting-edge materials have set new standards in efficiency, durability, and performance for a wide range of industries. Our bearings are engineered with precision and rigorously tested to withstand extreme conditions and heavy loads, ensuring reliable and long-lasting operation. Through continuous research and development, we continually improve our bearing technology to meet the evolving needs of our customers and the ever-changing demands of the market. We are confident that our bearings will continue to drive progress and enable new possibilities in various industries, propelling our clients towards success and growth. Join us in embracing the future with our superior bearing technology.

Bearing--An Ultimate FAQ Guide.

2.About Bearing production capacity

3.What are the differences between sealed and open bearings?

4.How do you determine the necessary lubrication for a bearing?

5.How does the size and design of a bearing affect its performance?

6.Can bearings be used for both rotary and linear motion?

7.How do you properly store and handle spare bearings?

8.How do you determine bearing load capacity?

9.What maintenance procedures should be followed for bearings?

10.Can bearings reduce friction?

11.About Bearing payment method

12.Can improper installation affect bearing performance?

13.How do bearings handle static and dynamic loads?

14.How do bearings handle misalignment and shaft deflection?

15.About the development history of Bearing factory

16.How do bearings handle high-speed rotations?

17.How do you seal bearings for use in high-moisture environments?

1.About Bearing production management system

The Bearing Production Management System (BPMS) is a comprehensive software solution designed to help bearing manufacturers manage their production processes. It provides a comprehensive set of tools to help manufacturers plan, monitor, and control their production operations. The system can be used to track production orders, manage inventory, and generate reports. It also provides features such as quality control, cost analysis, and production scheduling. BPMS can be used to improve efficiency and reduce costs in the bearing manufacturing process.

2.About Bearing production capacity

Bearing production capacity is determined by the size and complexity of the bearing, the type of material used, and the production process. The production capacity of a bearing manufacturer is typically determined by the number of machines and personnel available, the size of the factory, and the production process used. The production capacity of a bearing manufacturer can also be affected by the availability of raw materials, the quality of the raw materials, and the efficiency of the production process.

3.What are the differences between sealed and open bearings?

Sealed bearings are designed to keep out dirt, dust, and other contaminants, while open bearings are not. Sealed bearings are typically more expensive than open bearings, but they are also more reliable and require less maintenance. Sealed bearings are also better suited for applications that require protection from the environment, such as in wet or dusty conditions. Open bearings are typically used in applications where the environment is not a factor, such as in low-speed applications.

4.How do you determine the necessary lubrication for a bearing?

The necessary lubrication for a bearing depends on the type of bearing, the operating environment, and the load it is carrying. Generally, the lubricant should be selected based on the bearing manufacturer's recommendations. Factors such as temperature, speed, and load should also be taken into consideration when selecting the lubricant. Additionally, the lubricant should be compatible with the bearing material and the operating environment.

5.How does the size and design of a bearing affect its performance?

The size and design of a bearing can affect its performance in several ways. The size of the bearing affects the load capacity, speed, and accuracy of the bearing. A larger bearing can handle higher loads, run at higher speeds, and be more accurate than a smaller bearing. The design of the bearing affects the type of load it can handle, the amount of friction it produces, and the amount of noise it generates. A bearing with a higher contact angle can handle higher radial loads, while a bearing with a lower contact angle can handle higher thrust loads. The design of the bearing also affects the amount of friction it produces, which can affect the efficiency of the system. Finally, the design of the bearing affects the amount of noise it generates, which can be important in certain applications.

6.Can bearings be used for both rotary and linear motion?

Yes, bearings can be used for both rotary and linear motion. Bearings are used to reduce friction between two moving parts, allowing them to move more smoothly and efficiently. Depending on the type of bearing, they can be used for either rotary or linear motion.

7.How do you properly store and handle spare bearings?

1. Store spare bearings in a cool, dry place away from direct sunlight and moisture. 2. Handle spare bearings with care, using clean hands and gloves to avoid contamination. 3. Store bearings in their original packaging or in a sealed container to protect them from dust and dirt. 4. Label the container with the bearing type and size to ensure easy identification. 5. Inspect bearings for signs of wear or damage before use. 6. Use the correct lubricant for the bearing type and application. 7. Follow the manufacturer’s instructions for installation and maintenance.

8.How do you determine bearing load capacity?

Bearing load capacity is determined by the bearing's dynamic load rating, which is the maximum load a bearing can withstand while rotating. This rating is determined by the bearing's size, type, and construction. The dynamic load rating is usually expressed in kilograms or pounds. Other factors that can affect bearing load capacity include the bearing's operating temperature, lubrication, and speed.

9.What maintenance procedures should be followed for bearings?

1. Regularly inspect bearings for signs of wear or damage. 2. Clean bearings regularly with a soft cloth and lubricate them with a light oil or grease. 3. Check the bearing seals for any signs of damage or leakage. 4. Check the bearing housing for any signs of corrosion or damage. 5. Check the bearing mounting surfaces for any signs of wear or damage. 6. Check the bearing preload and adjust as necessary. 7. Check the bearing temperature and adjust as necessary. 8. Check the bearing alignment and adjust as necessary. 9. Check the bearing lubrication and adjust as necessary. 10. Check the bearing clearance and adjust as necessary.

10.Can bearings reduce friction?

Yes, bearings can reduce friction. Bearings are designed to reduce friction between two moving parts by providing a smooth surface for them to move against. They are used in a variety of applications, from automotive engines to industrial machinery.

11.About Bearing payment method

Bearing payment method is a payment system that allows customers to pay for goods and services using their mobile phones. It is a secure and convenient way to make payments, as customers can use their phones to make payments without having to enter their credit card information. The system is also designed to be secure, as customers can set up a PIN code to protect their account. Additionally, customers can also set up a limit on how much they can spend each month.

12.Can improper installation affect bearing performance?

Yes, improper installation can affect bearing performance. If a bearing is not installed correctly, it can cause premature failure, increased vibration, and increased noise. Improper installation can also cause misalignment, which can lead to increased friction and wear.

13.How do bearings handle static and dynamic loads?

Bearings are designed to handle both static and dynamic loads. Static loads are those that remain constant over time, such as the weight of a machine or the force of gravity. Dynamic loads are those that change over time, such as the force of a rotating shaft or the vibration of a machine. Bearings are designed to handle both types of loads by providing a smooth, low-friction surface for the load to move over. The bearing's design also helps to reduce the amount of wear and tear on the load-bearing components.

14.How do bearings handle misalignment and shaft deflection?

Bearings are designed to handle misalignment and shaft deflection by allowing the inner and outer races to move relative to each other. This is accomplished by using a combination of rolling elements, such as balls or rollers, and a cage that separates them. The rolling elements absorb the misalignment and shaft deflection, allowing the bearing to remain in contact with the shaft and maintain its load capacity.

15.About the development history of Bearing factory

The history of bearing factories dates back to the early 19th century, when the first bearing factories were established in Europe. The first bearing factories were established in England, France, and Germany. These factories produced bearings for use in a variety of industries, including the automotive, agricultural, and industrial sectors. In the early 20th century, bearing factories began to expand their production capabilities to include more specialized bearings. This allowed them to produce bearings for specific applications, such as those used in aircraft engines and other high-performance machinery. In the 1950s, bearing factories began to develop new technologies to improve the quality and performance of their products. This included the development of new materials, such as stainless steel and ceramic, as well as the introduction of computer-aided design and manufacturing processes. Today, bearing factories are still producing high-quality bearings for a variety of applications. They are also continuing to develop new technologies to improve the performance and reliability of their products.

16.How do bearings handle high-speed rotations?

Bearings are designed to handle high-speed rotations by reducing friction and allowing the rotating parts to move freely. They are typically made of hardened steel and contain rolling elements such as balls or rollers that reduce friction and allow the parts to move smoothly. The rolling elements are separated by a lubricant, which helps to reduce friction and heat buildup.

17.How do you seal bearings for use in high-moisture environments?

The best way to seal bearings for use in high-moisture environments is to use a combination of a labyrinth seal and a contact seal. Labyrinth seals are designed to keep out dirt and debris, while contact seals are designed to keep out moisture. Additionally, it is important to use a high-quality grease that is designed for use in high-moisture environments.

SKF Bearing

SKF Bearing NSK Bearing

NSK Bearing FAG Bearing

FAG Bearing TIMKEN Bearing

TIMKEN Bearing INA Bearing

INA Bearing NTN Bearing

NTN Bearing