Hongkong NKF Machinery Co., Limited. is an established supplier of bearings and power transmission products, serving customers in North America, Europe and Asia. With strong partnerships with industry-leading brands, we offer a diverse range of products to meet the needs of customers in various sectors including transportation, energy and agriculture. Our dedicated team of professionals is committed to providing customers with quality service and timely delivery.

Bearing is a crucial mechanical component used in various industries such as automotive, aerospace, and manufacturing. It is designed to allow rotational or linear movement between two or more parts, reducing friction and enabling smooth and efficient operation. The primary function of a bearing is to support and guide the rotating or sliding shaft, ensuring that the load is evenly distributed and the motion is precise. It also helps to extend the lifespan of machinery by reducing wear and tear. Bearings come in different types, including ball bearings, roller bearings, and plain bearings, each with unique features designed for specific applications. They are made of high-quality materials such as steel, ceramic, or polymer, depending on the intended use and environment. With its critical role in machinery, choosing the right bearing is essential for optimal performance and reliability.

about cylindrical roller bearing , we have carefully prepared some relevant professional knowledge documents for you. We hope to provide some help to you who have related product needs for needle bearing .

The Superior Strength of Our Bearing Products

1At NKF company, we understand that productivity is crucial for any business to thrive. That's why we have invested in cutting-edge needle bearing technology to boost efficiency and output. Our advanced bearings are designed to withstand heavy loads, reduce friction, and operate at high speeds, allowing for smoother and more efficient operation of machinery. With our bearings, you can expect increased uptime, decreased maintenance costs, and higher production rates. This means faster turnaround times, improved quality control, and ultimately, a more profitable and successful business. Trust our bearing technology to elevate your productivity to new heights.

2NKF high-quality needle bearing are precisely crafted to deliver exceptional performance in a wide range of applications. From heavy machinery and industrial equipment to automotive and consumer products, our bearings are engineered to perform with unparalleled precision.At the core of our precision is our state-of-the-art manufacturing process. We utilize the latest technologies and equipment to ensure every bearing meets the highest quality standards. Each component is carefully designed and tested to withstand extreme conditions and perform consistently.

NKF specialize in providing high-performance bearings that unlock unparalleled power and efficiency. Our bearings are engineered and manufactured with advanced technology and precision, ensuring smooth and reliable performance under even the toughest conditions. Whether it be in automotive, aerospace, or industrial applications, our bearings have been trusted by customers worldwide for their exceptional quality and durability. With a wide range of products to choose from, we are committed to providing our clients with the perfect solution to optimize their machinery. Experience the power of our high-performance bearings and elevate your operations to the next level. Trust us to unlock the full potential of your machinery.

NKF pride ourselves on the smooth operation of self-lubricating bearings. Our bearings are designed and manufactured with precision and care, using high-quality materials that ensure their durability and reliability. The self-lubricating feature eliminates the need for additional lubrication, making our bearings low maintenance and cost-effective. Moreover, our bearings are able to withstand high temperatures, heavy loads, and rigorous working conditions, making them ideal for a wide range of industries such as automotive, aerospace, and heavy machinery. Thanks to their innovative design and superior performance, our self-lubricating bearings provide a seamless and efficient operation, ensuring maximum productivity and minimal downtime. Trust us to provide you with the best self-lubricating bearings for all your industrial needs.

Bearing--An Ultimate FAQ Guide.

2.How do bearings contribute to noise reduction in machinery?

3.What are the differences between sealed and open bearings?

4.How do you troubleshoot bearing issues?

5.What are the different types of bearings?

6.About Bearing production skills training

7.About Bearing customization services

8.How do you determine bearing load capacity?

9.How do you determine the necessary lubrication for a bearing?

10.About Bearing production management system

11.How do you seal bearings for use in high-moisture environments?

12.What is the expected lifespan of a bearing?

13.How do you measure and specify bearing tolerances?

14.How do bearings handle corrosive environments?

15.How does the bearing material affect its performance and durability?

16.What is the effect of speed and temperature on bearing performance?

17.How do you select the right grease for a bearing?

18.About Bearing MOQ

19.How do bearings contribute to cost savings and increased productivity in machinery?

20.How do bearings contribute to machine reliability and uptime?

21.About Bearing production equipment

22.About Bearing inventory

1.How do you select the right bearing for a specific application?

1. Identify the load type and size: Determine the type and size of the load that the bearing will be supporting. This will help you determine the type of bearing that is best suited for the application. 2. Consider the environment: Consider the environment in which the bearing will be used. This will help you determine the type of material and lubrication that is best suited for the application. 3. Determine the speed and acceleration: Determine the speed and acceleration of the application. This will help you determine the type of bearing that is best suited for the application. 4. Consider the cost: Consider the cost of the bearing and the cost of the installation. This will help you determine the type of bearing that is best suited for the application. 5. Consider the availability: Consider the availability of the bearing and the availability of the installation. This will help you determine the type of bearing that is best suited for the application.

2.How do bearings contribute to noise reduction in machinery?

Bearings reduce noise in machinery by providing a smooth, low-friction surface for the moving parts to glide over. This reduces the amount of vibration and friction between the parts, which in turn reduces the amount of noise generated. Additionally, bearings can be designed to absorb some of the noise generated by the machinery, further reducing the overall noise level.

3.What are the differences between sealed and open bearings?

Sealed bearings are designed to keep out dirt, dust, and other contaminants, while open bearings are not. Sealed bearings are typically more expensive than open bearings, but they are also more reliable and require less maintenance. Sealed bearings are also better suited for applications that require protection from the environment, such as in wet or dusty conditions. Open bearings are typically used in applications where the environment is not a factor, such as in low-speed applications.

4.How do you troubleshoot bearing issues?

1. Inspect the bearing for signs of wear or damage. 2. Check the lubrication levels and condition of the bearing. 3. Check the alignment of the bearing and its components. 4. Check the mounting and installation of the bearing. 5. Check the operating environment of the bearing. 6. Check the speed and load of the bearing. 7. Check the vibration levels of the bearing. 8. Check the temperature of the bearing. 9. Check the noise levels of the bearing. 10. Check the electrical connections of the bearing.

5.What are the different types of bearings?

1. Ball Bearings: These are the most common type of bearing and are used in a wide variety of applications. They consist of an outer ring, inner ring, and a set of balls that are held in place by a cage. 2. Roller Bearings: These bearings use cylindrical rollers instead of balls to reduce friction and provide a smoother operation. They are typically used in applications that require high load capacity. 3. Thrust Bearings: These bearings are designed to handle axial loads and are commonly used in automotive transmissions and other applications that require high axial loads. 4. Tapered Roller Bearings: These bearings are designed to handle both radial and axial loads. They are commonly used in automotive wheel bearings and other applications that require high load capacity. 5. Spherical Roller Bearings: These bearings are designed to handle both radial and axial loads. They are commonly used in applications that require high load capacity and misalignment. 6. Needle Roller Bearings: These bearings are designed to handle high radial loads in a small space. They are commonly used in applications that require high load capacity and low friction. 7. Cylindrical Roller Bearings: These bearings are designed to handle high radial loads in a small space. They are commonly used in applications that require high load capacity and low friction.

6.About Bearing production skills training

Bearing production skills training is a type of training that focuses on teaching workers the skills needed to produce bearings. This type of training is important for any company that produces bearings, as it ensures that the bearings are produced to the highest quality standards. The training covers topics such as bearing design, manufacturing processes, quality control, and safety. It also covers topics such as bearing selection, installation, and maintenance. The training is typically conducted by experienced professionals who have a deep understanding of the bearing industry.

7.About Bearing customization services

Bearing customization services are offered by many companies to meet the specific needs of their customers. These services can include customizing the size, shape, material, and other features of a bearing to meet the customer’s exact requirements. This can be done for a variety of applications, including automotive, aerospace, medical, and industrial. Customized bearings can provide improved performance, longer life, and better reliability. They can also be designed to meet specific environmental conditions, such as extreme temperatures or high levels of vibration.

8.How do you determine bearing load capacity?

Bearing load capacity is determined by the bearing's dynamic load rating, which is the maximum load a bearing can withstand while rotating. This rating is determined by the bearing's size, type, and construction. The dynamic load rating is usually expressed in kilograms or pounds. Other factors that can affect bearing load capacity include the bearing's operating temperature, lubrication, and speed.

9.How do you determine the necessary lubrication for a bearing?

The necessary lubrication for a bearing depends on the type of bearing, the operating environment, and the load it is carrying. Generally, the lubricant should be selected based on the bearing manufacturer's recommendations. Factors such as temperature, speed, and load should also be taken into consideration when selecting the lubricant. Additionally, the lubricant should be compatible with the bearing material and the operating environment.

10.About Bearing production management system

The Bearing Production Management System (BPMS) is a comprehensive software solution designed to help bearing manufacturers manage their production processes. It provides a comprehensive set of tools to help manufacturers plan, monitor, and control their production operations. The system can be used to track production orders, manage inventory, and generate reports. It also provides features such as quality control, cost analysis, and production scheduling. BPMS can be used to improve efficiency and reduce costs in the bearing manufacturing process.

11.How do you seal bearings for use in high-moisture environments?

The best way to seal bearings for use in high-moisture environments is to use a combination of a labyrinth seal and a contact seal. Labyrinth seals are designed to keep out dirt and debris, while contact seals are designed to keep out moisture. Additionally, it is important to use a high-quality grease that is designed for use in high-moisture environments.

12.What is the expected lifespan of a bearing?

The expected lifespan of a bearing depends on the type of bearing, the environment in which it is used, and the amount of load it is subjected to. Generally, bearings can last anywhere from 3 to 10 years, with some bearings lasting up to 30 years or more.

13.How do you measure and specify bearing tolerances?

Bearing tolerances are typically measured in micrometers (μm) and specified in accordance with ISO or ABMA standards. The most common bearing tolerances are radial internal clearance, radial runout, axial runout, and radial clearance. Radial internal clearance is the difference between the inner and outer diameter of the bearing, and is typically specified in micrometers. Radial runout is the difference between the inner and outer diameter of the bearing when it is rotated, and is typically specified in micrometers. Axial runout is the difference between the inner and outer diameter of the bearing when it is rotated in the axial direction, and is typically specified in micrometers. Radial clearance is the difference between the inner and outer diameter of the bearing when it is rotated in the radial direction, and is typically specified in micrometers.

14.How do bearings handle corrosive environments?

Bearings can handle corrosive environments by using corrosion-resistant materials such as stainless steel, chrome steel, and ceramic. Additionally, bearings can be coated with a corrosion-resistant material such as zinc or a lubricant to protect them from corrosion.

15.How does the bearing material affect its performance and durability?

The bearing material affects its performance and durability in several ways. The material affects the bearing's ability to resist wear, corrosion, and temperature extremes. It also affects the bearing's ability to handle loads, its lubrication requirements, and its overall life expectancy. For example, bearings made from harder materials such as steel or ceramic can handle higher loads and last longer than bearings made from softer materials such as bronze or brass. Additionally, bearings made from materials with higher corrosion resistance can last longer in harsh environments.

16.What is the effect of speed and temperature on bearing performance?

Speed and temperature can have a significant effect on bearing performance. High speeds can cause increased friction and heat, which can lead to premature bearing failure. High temperatures can cause lubricants to break down, leading to increased friction and wear. Low temperatures can cause lubricants to thicken, leading to increased friction and wear. In general, bearings should be operated within the manufacturer's recommended speed and temperature range to ensure optimal performance.

17.How do you select the right grease for a bearing?

1. Determine the bearing type and operating conditions. Consider the bearing type, load, speed, temperature, and environment. 2. Select a grease based on the bearing type and operating conditions. Consider the base oil viscosity, thickener type, and additives. 3. Check the compatibility of the grease with the bearing material. 4. Check the compatibility of the grease with other components in the system. 5. Consider the cost and availability of the grease.

18.About Bearing MOQ

The minimum order quantity (MOQ) for bearings will vary depending on the type of bearing and the manufacturer. Generally, the MOQ for standard bearings is between 1 and 10 pieces, while the MOQ for custom bearings can be much higher.

19.How do bearings contribute to cost savings and increased productivity in machinery?

Bearings are essential components of machinery, and they can contribute to cost savings and increased productivity in several ways. First, bearings reduce friction, which helps to reduce energy consumption and wear and tear on the machinery. This can lead to lower maintenance costs and longer machine life. Second, bearings can help to reduce vibration, which can improve the accuracy and precision of the machinery. This can lead to higher quality products and increased productivity. Finally, bearings can help to reduce noise levels, which can improve the working environment and increase worker satisfaction.

20.How do bearings contribute to machine reliability and uptime?

Bearings are essential components of machines, providing support and allowing for smooth, efficient operation. They help to reduce friction, minimize wear and tear, and reduce noise and vibration. By reducing friction, bearings help to increase machine reliability and uptime by reducing the likelihood of breakdowns and malfunctions. Additionally, bearings help to reduce energy consumption, which can help to reduce operational costs.

21.About Bearing production equipment

Bearing production equipment is used to manufacture bearings, which are components used in a variety of machines and equipment. This equipment is used to produce bearings of various sizes and shapes, and can include machines such as lathes, grinders, and presses. The equipment is used to shape and finish the bearing components, and to assemble them into a complete bearing. The equipment is also used to test the bearings for quality and accuracy.

22.About Bearing inventory

Bearing inventory is a list of bearings that are available for purchase or use in a particular application. It includes information such as the type of bearing, its size, its load capacity, and its lubrication requirements. Bearing inventory is important for ensuring that the right bearing is used for the right application. It also helps to ensure that the bearings are properly maintained and replaced when necessary.

SKF Bearing

SKF Bearing NSK Bearing

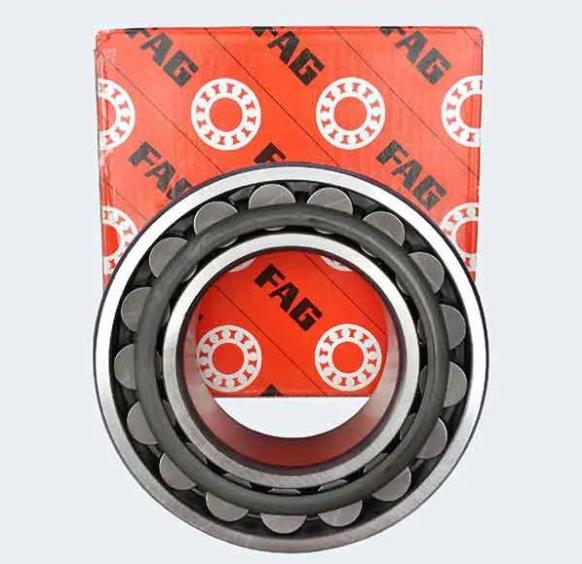

NSK Bearing FAG Bearing

FAG Bearing TIMKEN Bearing

TIMKEN Bearing INA Bearing

INA Bearing NTN Bearing

NTN Bearing