Hongkong NKF Machinery Co., Limited. is a reliable distributor and supplier of bearings and bearing-related products in various industries. With over 10 years of experience, we have built a solid reputation for quality, reliability and exceptional customer service. Our extensive product range includes ball bearings, roller bearings and mounted units, all sourced from top manufacturers. We also provide value-added services such as bearing repair and maintenance to ensure our customers' operations run smoothly.

Bearing is a crucial mechanical component that helps support and reduce friction between moving parts of a machinery or equipment. It consists of an outer and inner ring, rolling elements such as balls or rollers, and a cage to keep the rolling elements in place. The use of bearings enables smooth and efficient operation of various industrial, automotive, and machine applications. They are available in different materials such as metal, plastic, and ceramic, and can withstand a wide range of loads and speeds. Bearings are essential for reducing wear and tear, improving the performance and longevity of machines, and increasing productivity.

With the continuous development of technology, bearing products have evolved to meet the increasingly demanding requirements of different industries. From large industrial machines to household appliances, the importance of bearings cannot be underestimated. Trustworthy bearing products are essential for a stable, reliable, and efficient operation of equipment, making them a fundamental part of our modern world.

about camshaft bearing , we have carefully prepared some relevant professional knowledge documents for you. We hope to provide some help to you who have related product needs for tapered bearing .

The Superior Strength of Our Bearing Products

1NKF high-quality tapered bearing are precisely crafted to deliver exceptional performance in a wide range of applications. From heavy machinery and industrial equipment to automotive and consumer products, our bearings are engineered to perform with unparalleled precision.At the core of our precision is our state-of-the-art manufacturing process. We utilize the latest technologies and equipment to ensure every bearing meets the highest quality standards. Each component is carefully designed and tested to withstand extreme conditions and perform consistently.

2At NKF company, we understand that productivity is crucial for any business to thrive. That's why we have invested in cutting-edge tapered bearing technology to boost efficiency and output. Our advanced bearings are designed to withstand heavy loads, reduce friction, and operate at high speeds, allowing for smoother and more efficient operation of machinery. With our bearings, you can expect increased uptime, decreased maintenance costs, and higher production rates. This means faster turnaround times, improved quality control, and ultimately, a more profitable and successful business. Trust our bearing technology to elevate your productivity to new heights.

NKF bearing products are renowned for their versatility in meeting a wide range of industrial needs. From heavy duty machinery to precision instruments, our bearings are designed to deliver reliable and efficient performance in any application. With a variety of materials, sizes, and designs to choose from, our products are able to handle diverse operating conditions and meet the specific requirements of different industries. Furthermore, our bearings are manufactured with the highest quality standards, ensuring durability and longevity for our customers. No matter what your bearing needs are, our products are here to provide you with the utmost flexibility and functionality. Trust us to provide you with the perfect solution for all your bearing needs.

Our bearing products are equipped with cutting-edge features that make them stand out in the market. First and foremost, our bearings are made of high-quality materials that are durable and long-lasting. This ensures that they can withstand heavy loads and harsh environments.In terms of performance, our bearings are designed with precision engineering and advanced technology, resulting in smooth and precise operation. They also have low friction and high-speed capabilities, making them ideal for various applications.

Bearing--An Ultimate FAQ Guide.

2.What is the expected lifespan of a bearing?

3.How do you calculate the required bearing size for a specific load condition?

4.Can bearings be customized for specific applications?

5.About Bearing raw materials

6.What are the common causes of bearing failure?

7.About Bearing payment method

8.How do you ensure proper bearing alignment?

9.Can bearings be reused after being removed from machinery?

10.Can improper installation affect bearing performance?

11.How do you lubricate a bearing?

12.Can bearings handle high shock and impact loads?

13.Can bearings be used for high-temperature applications?

14.How does the size and design of a bearing affect its performance?

15.Can bearings be preloaded for increased stiffness?

16.What is the recommended clearance for proper bearing installation?

17.How does the bearing material affect its performance and durability?

18.About Bearing MOQ

1.What is the difference between precision and non-precision bearings?

Precision bearings are designed to provide higher levels of accuracy, repeatability, and durability than non-precision bearings. Precision bearings are typically used in applications that require higher levels of accuracy and repeatability, such as in medical and aerospace applications. Non-precision bearings are designed for general-purpose applications and are typically less expensive than precision bearings. Non-precision bearings are typically used in applications that do not require high levels of accuracy or repeatability, such as in automotive and industrial applications.

2.What is the expected lifespan of a bearing?

The expected lifespan of a bearing depends on the type of bearing, the environment in which it is used, and the amount of load it is subjected to. Generally, bearings can last anywhere from 3 to 10 years, with some bearings lasting up to 30 years or more.

3.How do you calculate the required bearing size for a specific load condition?

The required bearing size for a specific load condition can be calculated using the following formula: Bearing size = (Load x Bearing Factor) / (Bearing Life x RPM) Where: Load = The load applied to the bearing in pounds Bearing Factor = A factor determined by the bearing manufacturer Bearing Life = The expected life of the bearing in hours RPM = The speed of the bearing in revolutions per minute

4.Can bearings be customized for specific applications?

Yes, bearings can be customized for specific applications. Depending on the application, custom bearings can be designed to meet specific requirements such as size, load capacity, speed, and environmental conditions. Custom bearings can also be designed to meet specific performance requirements such as noise, vibration, and temperature.

5.About Bearing raw materials

Bearing raw materials are typically made from steel, bronze, brass, and other metals. They are used to make bearings, which are components that allow two parts to move relative to each other while reducing friction. The raw materials are typically machined to precise specifications to ensure that the bearings are able to perform their intended function.

6.What are the common causes of bearing failure?

1. Contamination: Contamination of the bearing or lubricant can cause excessive wear and premature bearing failure. 2. Poor lubrication: Insufficient or improper lubrication can cause excessive wear and premature bearing failure. 3. Overloading: Overloading of the bearing can cause excessive wear and premature bearing failure. 4. Misalignment: Misalignment of the bearing can cause excessive wear and premature bearing failure. 5. Poor installation: Poor installation of the bearing can cause excessive wear and premature bearing failure. 6. Corrosion: Corrosion of the bearing can cause excessive wear and premature bearing failure. 7. Fatigue: Fatigue of the bearing can cause excessive wear and premature bearing failure.

7.About Bearing payment method

Bearing payment method is a payment system that allows customers to pay for goods and services using their mobile phones. It is a secure and convenient way to make payments, as customers can use their phones to make payments without having to enter their credit card information. The system is also designed to be secure, as customers can set up a PIN code to protect their account. Additionally, customers can also set up a limit on how much they can spend each month.

8.How do you ensure proper bearing alignment?

1. Use a dial indicator to measure the runout of the bearing and shaft. 2. Use a straight edge to check for parallelism between the bearing and the shaft. 3. Use a feeler gauge to check for any gaps between the bearing and the shaft. 4. Use a laser alignment tool to measure the angularity between the bearing and the shaft. 5. Use shims to adjust the bearing alignment if necessary. 6. Use a bearing alignment tool to ensure proper alignment.

9.Can bearings be reused after being removed from machinery?

Yes, bearings can be reused after being removed from machinery, provided they are in good condition and have not been damaged. However, it is important to inspect the bearings for any signs of wear or damage before reusing them.

10.Can improper installation affect bearing performance?

Yes, improper installation can affect bearing performance. If a bearing is not installed correctly, it can cause premature failure, increased vibration, and increased noise. Improper installation can also cause misalignment, which can lead to increased friction and wear.

11.How do you lubricate a bearing?

1. Clean the bearing and surrounding area with a clean cloth. 2. Apply a thin layer of lubricant to the bearing. 3. Rotate the bearing to spread the lubricant evenly. 4. Wipe away any excess lubricant.

12.Can bearings handle high shock and impact loads?

Yes, bearings can handle high shock and impact loads, depending on the type of bearing. Some bearings are specifically designed to handle high shock and impact loads, such as spherical roller bearings, tapered roller bearings, and angular contact ball bearings.

13.Can bearings be used for high-temperature applications?

Yes, some bearings are designed for high-temperature applications. These bearings are typically made from materials that can withstand high temperatures, such as ceramic or stainless steel.

14.How does the size and design of a bearing affect its performance?

The size and design of a bearing can affect its performance in several ways. The size of the bearing affects the load capacity, speed, and accuracy of the bearing. A larger bearing can handle higher loads, run at higher speeds, and be more accurate than a smaller bearing. The design of the bearing affects the type of load it can handle, the amount of friction it produces, and the amount of noise it generates. A bearing with a higher contact angle can handle higher radial loads, while a bearing with a lower contact angle can handle higher thrust loads. The design of the bearing also affects the amount of friction it produces, which can affect the efficiency of the system. Finally, the design of the bearing affects the amount of noise it generates, which can be important in certain applications.

15.Can bearings be preloaded for increased stiffness?

Yes, bearings can be preloaded for increased stiffness. Preloading is a process in which a force is applied to a bearing before it is installed in a machine. This force compresses the bearing and increases its stiffness, which can help reduce vibration and improve the performance of the machine.

16.What is the recommended clearance for proper bearing installation?

The recommended clearance for proper bearing installation is 0.001 to 0.0015 inches.

17.How does the bearing material affect its performance and durability?

The bearing material affects its performance and durability in several ways. The material affects the bearing's ability to resist wear, corrosion, and temperature extremes. It also affects the bearing's ability to handle loads, its lubrication requirements, and its overall life expectancy. For example, bearings made from harder materials such as steel or ceramic can handle higher loads and last longer than bearings made from softer materials such as bronze or brass. Additionally, bearings made from materials with higher corrosion resistance can last longer in harsh environments.

18.About Bearing MOQ

The minimum order quantity (MOQ) for bearings will vary depending on the type of bearing and the manufacturer. Generally, the MOQ for standard bearings is between 1 and 10 pieces, while the MOQ for custom bearings can be much higher.

SKF Bearing

SKF Bearing NSK Bearing

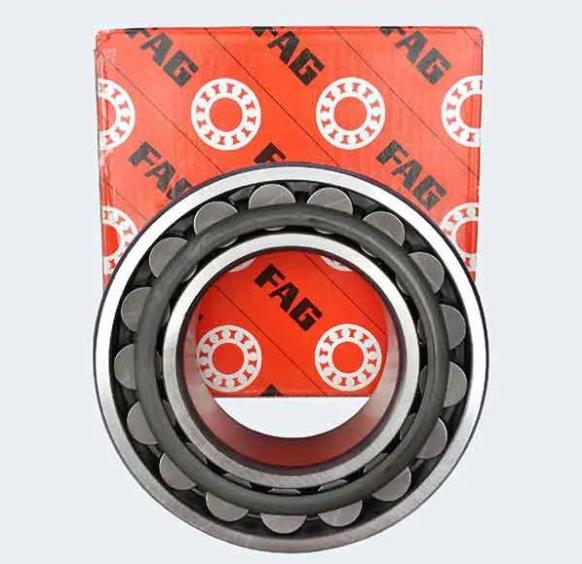

NSK Bearing FAG Bearing

FAG Bearing TIMKEN Bearing

TIMKEN Bearing INA Bearing

INA Bearing NTN Bearing

NTN Bearing