Hongkong NKF Machinery Co., Limited. is a reliable distributor and supplier of bearings and bearing-related products in various industries. With over 10 years of experience, we have built a solid reputation for quality, reliability and exceptional customer service. Our extensive product range includes ball bearings, roller bearings and mounted units, all sourced from top manufacturers. We also provide value-added services such as bearing repair and maintenance to ensure our customers' operations run smoothly.

Bearing is a crucial mechanical component that helps support and reduce friction between moving parts of a machinery or equipment. It consists of an outer and inner ring, rolling elements such as balls or rollers, and a cage to keep the rolling elements in place. The use of bearings enables smooth and efficient operation of various industrial, automotive, and machine applications. They are available in different materials such as metal, plastic, and ceramic, and can withstand a wide range of loads and speeds. Bearings are essential for reducing wear and tear, improving the performance and longevity of machines, and increasing productivity. With the continuous development of technology, bearing products have evolved to meet the increasingly demanding requirements of different industries. From large industrial machines to household appliances, the importance of bearings cannot be underestimated. Trustworthy bearing products are essential for a stable, reliable, and efficient operation of equipment, making them a fundamental part of our modern world.

about clutch bearing , we have carefully prepared some relevant professional knowledge documents for you. We hope to provide some help to you who have related product needs for thrust ball bearing .

The Unmatched Accuracy of Our Bearings

1NKF high-quality thrust ball bearing are precisely crafted to deliver exceptional performance in a wide range of applications. From heavy machinery and industrial equipment to automotive and consumer products, our bearings are engineered to perform with unparalleled precision.At the core of our precision is our state-of-the-art manufacturing process. We utilize the latest technologies and equipment to ensure every bearing meets the highest quality standards. Each component is carefully designed and tested to withstand extreme conditions and perform consistently.

2NKF advanced thrust ball bearing materials offer a wide range of benefits that make them the preferred choice for many different industries. Firstly, our materials are extremely durable and have a longer lifespan compared to traditional materials, thus reducing the need for frequent replacements and maintenance. This results in cost savings for businesses in terms of both time and money.

NKF pride ourselves on the smooth operation of self-lubricating bearings. Our bearings are designed and manufactured with precision and care, using high-quality materials that ensure their durability and reliability. The self-lubricating feature eliminates the need for additional lubrication, making our bearings low maintenance and cost-effective. Moreover, our bearings are able to withstand high temperatures, heavy loads, and rigorous working conditions, making them ideal for a wide range of industries such as automotive, aerospace, and heavy machinery. Thanks to their innovative design and superior performance, our self-lubricating bearings provide a seamless and efficient operation, ensuring maximum productivity and minimal downtime. Trust us to provide you with the best self-lubricating bearings for all your industrial needs.

With years of experience and expertise, our bearings have become the top choice for demanding applications. Our bearings are specifically designed and engineered to withstand heavy loads, high speeds, and harsh environments, making them suitable for a wide range of industries including automotive, aerospace, and industrial manufacturing.One of the main reasons our bearings stand out is their superior quality. We only use the best materials and employ the latest manufacturing techniques to ensure unmatched durability and reliability. This not only results in longer product life but also minimizes maintenance and replacement costs.

Bearing--An Ultimate FAQ Guide.

2.How do bearings handle corrosive environments?

3.About Bearing MOQ

4.Can bearings operate in extreme temperatures?

5.How do you seal bearings for use in high-moisture environments?

6.About Bearing raw materials

7.About Bearing production management system

8.What is the difference between a ball bearing and a roller bearing?

9.Can bearings handle high shock and impact loads?

10.How do bearings handle high-speed rotations?

11.What is the recommended maintenance schedule for bearings?

12.What is the role of a bearing cage or retainer?

13.How does a bearing function?

14.How do you determine bearing load capacity?

15.How do you ensure proper bearing alignment?

16.What is the role of seals and shields in bearing protection?

17.What are the factors that affect bearing service life?

18.How do you select the right grease for a bearing?

19.About Bearing delivery date

20.How does contamination affect bearing performance?

21.What is the process of mounting and dismounting bearings?

1.Can bearings be customized for specific applications?

Yes, bearings can be customized for specific applications. Depending on the application, custom bearings can be designed to meet specific requirements such as size, load capacity, speed, and environmental conditions. Custom bearings can also be designed to meet specific performance requirements such as noise, vibration, and temperature.

2.How do bearings handle corrosive environments?

Bearings can handle corrosive environments by using corrosion-resistant materials such as stainless steel, chrome steel, and ceramic. Additionally, bearings can be coated with a corrosion-resistant material such as zinc or a lubricant to protect them from corrosion.

3.About Bearing MOQ

The minimum order quantity (MOQ) for bearings will vary depending on the type of bearing and the manufacturer. Generally, the MOQ for standard bearings is between 1 and 10 pieces, while the MOQ for custom bearings can be much higher.

4.Can bearings operate in extreme temperatures?

Yes, bearings can operate in extreme temperatures. Depending on the type of bearing, they can be designed to withstand temperatures ranging from -200°C to +400°C.

5.How do you seal bearings for use in high-moisture environments?

The best way to seal bearings for use in high-moisture environments is to use a combination of a labyrinth seal and a contact seal. Labyrinth seals are designed to keep out dirt and debris, while contact seals are designed to keep out moisture. Additionally, it is important to use a high-quality grease that is designed for use in high-moisture environments.

6.About Bearing raw materials

Bearing raw materials are typically made from steel, bronze, brass, and other metals. They are used to make bearings, which are components that allow two parts to move relative to each other while reducing friction. The raw materials are typically machined to precise specifications to ensure that the bearings are able to perform their intended function.

7.About Bearing production management system

The Bearing Production Management System (BPMS) is a comprehensive software solution designed to help bearing manufacturers manage their production processes. It provides a comprehensive set of tools to help manufacturers plan, monitor, and control their production operations. The system can be used to track production orders, manage inventory, and generate reports. It also provides features such as quality control, cost analysis, and production scheduling. BPMS can be used to improve efficiency and reduce costs in the bearing manufacturing process.

8.What is the difference between a ball bearing and a roller bearing?

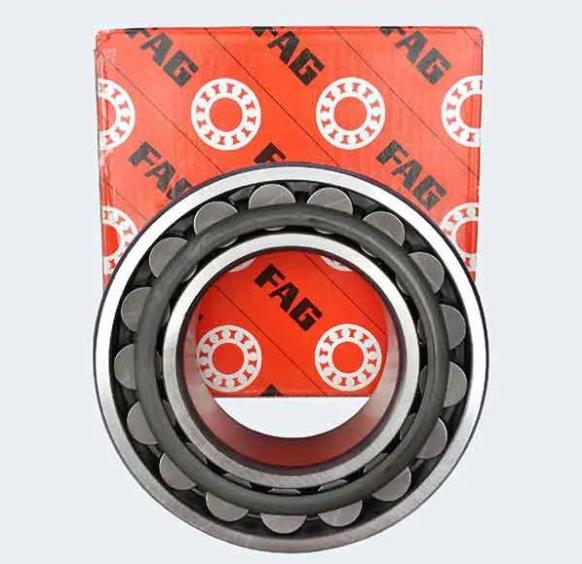

A ball bearing is a type of bearing that uses small metal balls to reduce friction between moving parts. Ball bearings are used in a wide variety of applications, from automotive to industrial machinery. A roller bearing is a type of bearing that uses cylindrical rollers to reduce friction between moving parts. Roller bearings are typically used in applications that require higher load capacity than a ball bearing can provide.

9.Can bearings handle high shock and impact loads?

Yes, bearings can handle high shock and impact loads, depending on the type of bearing. Some bearings are specifically designed to handle high shock and impact loads, such as spherical roller bearings, tapered roller bearings, and angular contact ball bearings.

10.How do bearings handle high-speed rotations?

Bearings are designed to handle high-speed rotations by reducing friction and allowing the rotating parts to move freely. They are typically made of hardened steel and contain rolling elements such as balls or rollers that reduce friction and allow the parts to move smoothly. The rolling elements are separated by a lubricant, which helps to reduce friction and heat buildup.

11.What is the recommended maintenance schedule for bearings?

The recommended maintenance schedule for bearings depends on the type of bearing and the application. Generally, bearings should be inspected and lubricated at least once a year, or more frequently if the application is in a harsh environment. Additionally, bearings should be replaced when they show signs of wear or damage.

12.What is the role of a bearing cage or retainer?

A bearing cage or retainer is a component of a bearing assembly that helps to keep the rolling elements in place and evenly spaced. It also helps to reduce friction and noise, and can help to protect the bearing from dirt and debris.

13.How does a bearing function?

A bearing is a mechanical device that is used to reduce friction between two moving parts. It works by allowing the parts to move relative to each other while reducing the amount of friction between them. Bearings are typically made of metal and contain rolling elements such as balls or rollers that reduce friction and allow the parts to move more freely.

14.How do you determine bearing load capacity?

Bearing load capacity is determined by the bearing's dynamic load rating, which is the maximum load a bearing can withstand while rotating. This rating is determined by the bearing's size, type, and construction. The dynamic load rating is usually expressed in kilograms or pounds. Other factors that can affect bearing load capacity include the bearing's operating temperature, lubrication, and speed.

15.How do you ensure proper bearing alignment?

1. Use a dial indicator to measure the runout of the bearing and shaft. 2. Use a straight edge to check for parallelism between the bearing and the shaft. 3. Use a feeler gauge to check for any gaps between the bearing and the shaft. 4. Use a laser alignment tool to measure the angularity between the bearing and the shaft. 5. Use shims to adjust the bearing alignment if necessary. 6. Use a bearing alignment tool to ensure proper alignment.

16.What is the role of seals and shields in bearing protection?

Seals and shields are used to protect bearings from dirt, dust, and other contaminants. They also help to keep lubricants in and contaminants out, and can help to reduce friction and wear. Seals and shields can also help to reduce noise and vibration, and can help to extend the life of the bearing.

17.What are the factors that affect bearing service life?

1. Bearing type: Different types of bearings have different service lives. 2. Operating conditions: The operating conditions of the bearing, such as speed, load, temperature, and lubrication, can affect its service life. 3. Quality of the bearing: The quality of the bearing, such as the material used and the manufacturing process, can affect its service life. 4. Maintenance: Regular maintenance and inspection of the bearing can help to extend its service life. 5. Environment: The environment in which the bearing is used can affect its service life.

18.How do you select the right grease for a bearing?

1. Determine the bearing type and operating conditions. Consider the bearing type, load, speed, temperature, and environment. 2. Select a grease based on the bearing type and operating conditions. Consider the base oil viscosity, thickener type, and additives. 3. Check the compatibility of the grease with the bearing material. 4. Check the compatibility of the grease with other components in the system. 5. Consider the cost and availability of the grease.

19.About Bearing delivery date

The delivery date of a bearing depends on the type of bearing, the quantity of bearings ordered, and the availability of the bearing. Generally, bearings can be delivered within a few days to a few weeks.

20.How does contamination affect bearing performance?

Contamination can cause a number of issues that can affect bearing performance. Contamination can cause increased friction, increased wear, and increased heat. This can lead to premature bearing failure, increased noise, and vibration. Contamination can also cause corrosion, which can lead to bearing seizure and failure.

21.What is the process of mounting and dismounting bearings?

Mounting: 1. Clean the bearing and the shaft. 2. Apply a thin layer of lubricant to the bearing and the shaft. 3. Place the bearing on the shaft. 4. Secure the bearing in place with a retaining ring or other appropriate method. Dismounting: 1. Remove the retaining ring or other securing device. 2. Carefully tap the bearing off the shaft using a soft hammer. 3. Clean the bearing and the shaft. 4. Inspect the bearing and the shaft for any damage.

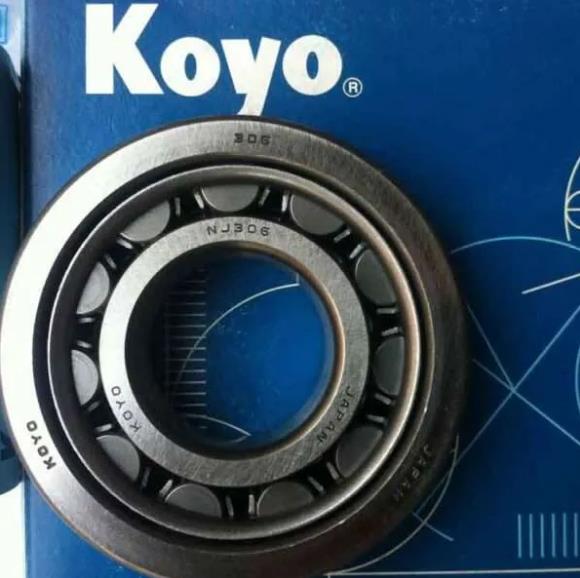

Tag:SKF Bearing,NSK Bearing,FAG Bearing

SKF Bearing

SKF Bearing NSK Bearing

NSK Bearing FAG Bearing

FAG Bearing TIMKEN Bearing

TIMKEN Bearing INA Bearing

INA Bearing NTN Bearing

NTN Bearing