| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Retail, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other |

| Bore Size | 8 - 21 mm |

| Precision Rating | Z1 Z2 Z3 |

| Place of Origin | Hongkong, China |

| Type | BALL |

| Structure | Deep Groove |

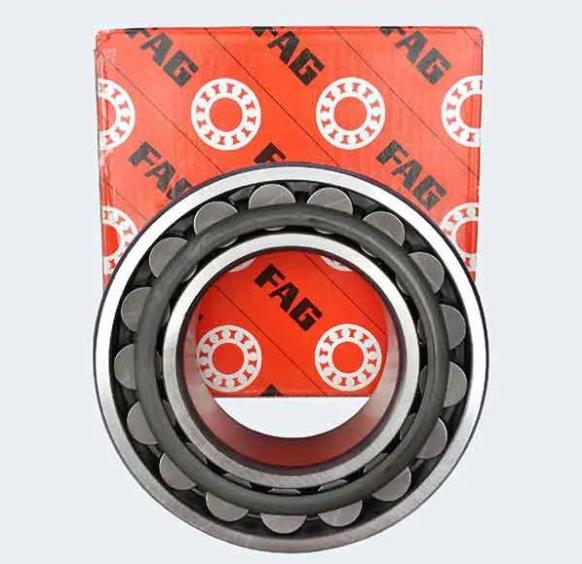

| Model Number | skf,FAG,NTAK,NTN,Iko,Koyo |

| Seals Type | OPEN |

| Product name | 1313TV |

| ID Dia | 3- 22mm |

| Thickness | 5-31mm |

| Bearing type | Ball Bearing |

| Stock | Rich |

| OEM | Accept |

| Delivery time | 8 Days |

| Package | Tube / Carton Box |

| Number of Row | Double row |

| Supply Ability | 118702 Piece/Pieces per Month |

| Quantity (pieces) | 6419 - 8441 |

| Lead time (days) | 11 |

6312N bearings FAQs Guide Our 6312N bearings are essential components in various machinery and equipment, providing support and reducing friction for moving parts. With years of experience and advanced technology, we are dedicated to producing 6312N bearings that meet the highest standards of quality, durability, and performance. Our commitment to excellence has made us a trusted supplier for industries such as automotive, aerospace, and industrial manufacturing. Let us introduce you to our diverse range of bearing products and how they can meet your specific needs.

2.About 6312N bearings production management system

3.About 6312N bearings raw material procurement system

4.How do 6312N bearingss handle static and dynamic loads?

5.Can improper installation affect 6312N bearings performance?

6.How do you ensure proper 6312N bearings alignment?

7.About 6312N bearings payment method

8.How does the 6312N bearings material affect its performance and durability?

9.About 6312N bearings origin

10.How do 6312N bearings handle radial and axial play?

11.What is the recommended maintenance schedule for 6312N bearings?

12.Can 6312N bearingss be used for both rotary and linear motion?

13.Can 6312N bearings be repaired or do they need to be replaced?

14.What factors should be considered when choosing a 6312N bearings?

15.How do 6312N bearingss handle corrosive environments?

1.How do 6312N bearingss handle high-speed rotations?

Being one of the top 6312NBearings manufacturers in China, We attach great importance to this detail

Bearings are designed to handle high-speed rotations by reducing friction and allowing the rotating parts to move freely

They are typically made of hardened steel and contain rolling elements such as balls or rollers that reduce friction and allow the parts to move smoothly

The rolling elements are separated by a lubricant, which helps to reduce friction and heat buildup

2.About 6312N bearings production management system

The Bearing Production Management System (BPMS) is a comprehensive software solution designed to help bearing manufacturers manage their production processes

It provides a comprehensive set of tools to help manufacturers plan, monitor, and control their production operations

The system can be used to track production orders, manage inventory, and generate reports

It also provides features such as quality control, cost analysis, and production scheduling

BPMS can be used to improve efficiency and reduce costs in the bearing manufacturing process

3.About 6312N bearings raw material procurement system

The Bearing raw material procurement system is a software solution designed to streamline the process of procuring raw materials for the production of bearings

The system automates the process of sourcing, ordering, and tracking raw materials, allowing for more efficient and cost-effective procurement

The system also provides visibility into the entire supply chain, allowing for better decision-making and improved supplier relationships

Additionally, the system can be integrated with existing ERP systems, providing a seamless experience for users

4.How do 6312N bearingss handle static and dynamic loads?

We pay attention to the introduction and training of talents, scientifically regulate the management system, and focus on cultural construction and team cohesion

Bearings are designed to handle both static and dynamic loads

Static loads are those that remain constant over time, such as the weight of a machine or the force of gravity

Dynamic loads are those that change over time, such as the force of a rotating shaft or the vibration of a machine

Bearings are designed to handle both types of loads by providing a smooth, low-friction surface for the load to move over

The bearing's design also helps to reduce the amount of wear and tear on the load-bearing components

5.Can improper installation affect 6312N bearings performance?

We have flexible production capacity

Whether you are large orders or small orders, you can produce and release goods in a timely manner to meet customer needs

Yes, improper installation can affect bearing performance

If a bearing is not installed correctly, it can cause premature failure, increased vibration, and increased noise

Improper installation can also cause misalignment, which can lead to increased friction and wear

6.How do you ensure proper 6312N bearings alignment?

1

Use a dial indicator to measure the runout of the bearing and shaft

2

Use a straight edge to check for parallelism between the bearing and the shaft

3

Use a feeler gauge to check for the proper gap between the bearing and the shaft

4

Use a laser alignment tool to measure the angularity between the bearing and the shaft

5

Use shims to adjust the bearing alignment if necessary

6

Use a bearing alignment tool to ensure the bearing is properly aligned

7.About 6312N bearings payment method

Bearing payment method is a payment system that allows customers to pay for goods and services using their mobile phones

It is a secure and convenient way to make payments, as customers can use their phones to make payments without having to enter their credit card information

The system is also designed to be secure, as customers can set up a PIN code to protect their account

Additionally, customers can also set up a limit on how much they can spend each month

8.How does the 6312N bearings material affect its performance and durability?

We enjoy high authority and influence in the industry and continue to innovate products and service models

The bearing material affects its performance and durability in several ways

The material affects the bearing's ability to resist wear, corrosion, and temperature extremes

It also affects the bearing's ability to handle loads, its lubrication requirements, and its overall life expectancy

For example, bearings made from harder materials such as steel or ceramic can handle higher loads and last longer than bearings made from softer materials such as bronze or plastic

Additionally, bearings made from materials with higher corrosion resistance can last longer in harsh environments

9.About 6312N bearings origin

Bearing origin is a term used to describe the source of a bearing's components

It is important to know the origin of a bearing because it can affect the quality and performance of the bearing

The origin of a bearing can be determined by looking at the markings on the bearing itself, or by contacting the manufacturer

10.How do 6312N bearings handle radial and axial play?

Bearings are designed to handle radial and axial play by using a combination of rolling elements, such as balls or rollers, and a cage or retainer to keep the elements in place

The rolling elements are designed to move freely within the bearing, allowing for a certain amount of radial and axial play

The cage or retainer helps to keep the elements in place and prevent them from moving too far, which could cause damage to the bearing

11.What is the recommended maintenance schedule for 6312N bearings?

The recommended maintenance schedule for bearings depends on the type of bearing and the application

Generally, bearings should be inspected and lubricated at least once a year, or more frequently if the application is in a harsh environment

Additionally, bearings should be replaced when they show signs of wear or damage

12.Can 6312N bearingss be used for both rotary and linear motion?

Our 6312N products undergo strict quality control to ensure customer satisfaction

Yes, bearings can be used for both rotary and linear motion

Bearings are used to reduce friction between two moving parts, allowing them to move more smoothly and efficiently

Depending on the type of bearing, they can be used for either rotary or linear motion

13.Can 6312N bearings be repaired or do they need to be replaced?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers

In some cases, bearings can be repaired, but it depends on the type of bearing and the extent of the damage

In general, if the bearing is severely damaged, it is best to replace it

14.What factors should be considered when choosing a 6312N bearings?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced 6312N products

1

Load: The bearing must be able to support the load it will be subjected to

2

Speed: The bearing must be able to handle the speed of the application

3

Environment: The bearing must be able to withstand the environmental conditions it will be exposed to

4

Precision: The bearing must be able to provide the necessary precision for the application

5

Lubrication: The bearing must be able to handle the lubrication requirements of the application

6

Cost: The bearing must be cost-effective for the application

7

Availability: The bearing must be readily available for the application

15.How do 6312N bearingss handle corrosive environments?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process

Bearings can handle corrosive environments by using corrosion-resistant materials such as stainless steel, chrome steel, and ceramic

Additionally, bearings can be coated with a corrosion-resistant material such as zinc or a lubricant to protect them from corrosion

Tag:3209A,6211-RS,7038C,NUP319E FAG,3204A

Free Delivery

Orders from 70,00 Euro will be shipped free of charge within Germany and to Austria with GLS! Up to 69,99 Euro order volume we charge only 3,90 Euro with GLS. For shipment with DHL GoGreen within Germany we charge only 5,90 Euro up to 69,99 Euro order volume or 2,00 Euro for orders from 70,00 Euro.

Delivery Time: Ready for Shipping within 24h

We try hard to make as much orders as possible ready for shipping within 24 hours (after receiption of payment), because we generally offer only items in our online shop which we have currently on stock. The independent official seal for excellence in shipment always shows you, have fast we are currently working (make your order ready for pick-up by our logistics partner).

Delivery areas:

We deliver to the following countries: Germany, Austria, Switzerland and Belgium, Bulgaria, Denmark, Estonia, Finland, France, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Liechtenstein, Luxembourg, Netherlands, Norway, Poland, Portugal, Romania, Russia, Sweden, Switzerland, Slovakia, Slovenia, Spain, Czech Republic, Hungary, USA. Please find information about delivery costs below. We usually do, but currently do NOT ship to: UK and Norway. Please visit this site frequently for updates or contact our customer service.

Returns

If a product does not meet your expectation for any reason, you can return the product without ifs and buts. To make it even more easy for you, we recommend to use the attached return form and the return stickers free of charge within 30 days of receipt. Just drop the parcel at your nearest GLS parcel shop or DHL branch (depending on the provided return label) in Germany. Of course this is not a compulsory requirement to exercise your right of withdrawal. Find more information on our website for your right of withdrawal.

SKF Bearing

SKF Bearing NSK Bearing

NSK Bearing FAG Bearing

FAG Bearing TIMKEN Bearing

TIMKEN Bearing INA Bearing

INA Bearing NTN Bearing

NTN Bearing