| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Retail, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other |

| Bore Size | 2 - 28 mm |

| Precision Rating | Z1 Z2 Z3 |

| Place of Origin | Hongkong, China |

| Type | BALL |

| Structure | Deep Groove |

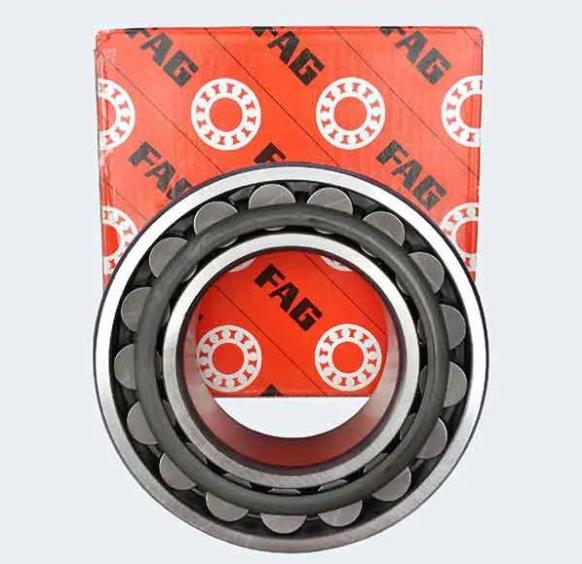

| Model Number | skf,FAG,NTAK,NTN,Iko,Koyo |

| Seals Type | OPEN |

| Product name | 31308 FAG |

| ID Dia | 5- 27mm |

| Thickness | 3-27mm |

| Bearing type | Ball Bearing |

| Stock | Rich |

| OEM | Accept |

| Delivery time | 10 Days |

| Package | Tube / Carton Box |

| Number of Row | Double row |

| Supply Ability | 100518 Piece/Pieces per Month |

| Quantity (pieces) | 6376 - 9189 |

| Lead time (days) | 9 |

6010N FAG bearings FAQs Guide Our 6010N FAG bearings are essential components in various machinery and equipment, providing support and reducing friction for moving parts. With years of experience and advanced technology, we are dedicated to producing 6010N FAG bearings that meet the highest standards of quality, durability, and performance. Our commitment to excellence has made us a trusted supplier for industries such as automotive, aerospace, and industrial manufacturing. Let us introduce you to our diverse range of bearing products and how they can meet your specific needs.

2.What are the common causes of 6010N FAG bearings failure?

3.What is the difference between a radial and thrust 6010N FAG bearings?

4.How does the size and design of a 6010N FAG bearings affect its performance?

5.What are the differences between sealed and open 6010N FAG bearingss?

6.How do you troubleshoot 6010N FAG bearings issues?

7.How do 6010N FAG bearings help in reducing wear and tear of moving parts?

8.How do 6010N FAG bearings handle shock and vibration?

9.How do 6010N FAG bearings help in weight reduction for equipment?

10.How do 6010N FAG bearings contribute to machine efficiency?

11.Which industries heavily rely on 6010N FAG bearingss?

12.How do you determine 6010N FAG bearings load capacity?

13.How do you determine the necessary lubrication for a 6010N FAG bearings?

1.How do 6010N FAG bearings contribute to noise reduction in machinery?

Our products & services cover a wide range of areas and meet the needs of different fields

Bearings reduce noise in machinery by providing a smooth, low-friction surface for the moving parts to glide over

This reduces the amount of vibration and friction between the parts, which in turn reduces the amount of noise generated

Additionally, bearings can be designed to absorb some of the noise generated by the machinery, further reducing the overall noise level

2.What are the common causes of 6010N FAG bearings failure?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously

1

Contamination: Contamination of the bearing or lubricant can cause excessive wear and premature bearing failure

2

Poor lubrication: Insufficient or improper lubrication can cause excessive wear and premature bearing failure

3

Overloading: Overloading of the bearing can cause excessive wear and premature bearing failure

4

Misalignment: Misalignment of the bearing can cause excessive wear and premature bearing failure

5

Poor installation: Poor installation of the bearing can cause excessive wear and premature bearing failure

6

Corrosion: Corrosion of the bearing can cause excessive wear and premature bearing failure

7

Fatigue: Fatigue of the bearing can cause excessive wear and premature bearing failure

3.What is the difference between a radial and thrust 6010N FAG bearings?

A radial bearing is designed to support a load that is perpendicular to the shaft, while a thrust bearing is designed to support a load that is parallel to the shaft

Radial bearings are typically used in applications such as electric motors, pumps, and compressors, while thrust bearings are used in applications such as turbines, gearboxes, and automotive transmissions

4.How does the size and design of a 6010N FAG bearings affect its performance?

We continue to invest in research and development and continue to launch innovative products

The size and design of a bearing can affect its performance in several ways

The size of the bearing affects the load capacity, speed, and accuracy of the bearing

A larger bearing can handle higher loads, run at higher speeds, and be more accurate than a smaller bearing

The design of the bearing affects the type of load it can handle, the amount of friction it produces, and the amount of noise it generates

A bearing with a higher contact angle can handle higher radial loads, while a bearing with a lower contact angle can handle higher thrust loads

The design of the bearing also affects the amount of friction it produces, which can affect the efficiency of the system

Finally, the design of the bearing affects the amount of noise it generates, which can be important in certain applications

5.What are the differences between sealed and open 6010N FAG bearingss?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system

Sealed bearings are designed to keep out dirt, dust, and other contaminants, while open bearings are not

Sealed bearings are typically more expensive than open bearings, but they are also more reliable and require less maintenance

Sealed bearings are also better suited for applications that require protection from the environment, such as in wet or dusty conditions

Open bearings are typically used in applications where the environment is not a factor, such as in low-speed applications

6.How do you troubleshoot 6010N FAG bearings issues?

We have advantages in marketing and channel expansion

Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services

1

Inspect the bearing for signs of wear or damage

2

Check the lubrication levels and condition of the bearing

3

Check the alignment of the bearing and its components

4

Check the mounting and installation of the bearing

5

Check the operating environment of the bearing

6

Check the speed and load of the bearing

7

Check the vibration levels of the bearing

8

Check the temperature of the bearing

9

Check the noise levels of the bearing

10

Check the electrical connections of the bearing

7.How do 6010N FAG bearings help in reducing wear and tear of moving parts?

Our mission is to provide customers with the best solutions for 6010N FAG

Bearings help reduce wear and tear of moving parts by providing a smooth surface for the parts to move against

The bearing's smooth surface reduces friction, which in turn reduces wear and tear on the parts

Additionally, bearings can help absorb shock and vibration, which can also reduce wear and tear on the parts

8.How do 6010N FAG bearings handle shock and vibration?

We are a new 6010N FAGBearings manufacturer

Bearings are designed to handle shock and vibration by using a combination of materials and design features

The bearing components are typically made of hardened steel, which is able to withstand high levels of shock and vibration

The bearing design also includes features such as lubrication grooves, which help to reduce friction and wear, and internal clearance, which helps to absorb shock and vibration

9.How do 6010N FAG bearings help in weight reduction for equipment?

Bearings help reduce weight in equipment by reducing friction and allowing components to move more freely

This reduces the amount of energy needed to move the equipment, which in turn reduces the overall weight of the equipment

Additionally, bearings can be made from lightweight materials such as aluminum or plastic, which further reduces the weight of the equipment

10.How do 6010N FAG bearings contribute to machine efficiency?

We have established a good reputation and reliable partnerships within the 6010N FAG industry

Bearings are essential components of machines that help to reduce friction and improve efficiency

They allow parts to move smoothly and reduce the amount of energy needed to move them

By reducing friction, bearings help to reduce wear and tear on the machine, which can help to extend its life

Additionally, bearings can help to reduce noise and vibration, which can improve the overall efficiency of the machine

11.Which industries heavily rely on 6010N FAG bearingss?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail

1

Automotive industry

2

Aerospace industry

3

Heavy machinery industry

4

Robotics industry

5

Agriculture industry

6

Marine industry

7

Construction industry

8

Power generation industry

9

Medical industry

10

Textile industry

12.How do you determine 6010N FAG bearings load capacity?

We actively participate in the 6010N FAGBearings industry associations and organization activities

The corporate social responsibility performed well, and the focus of brand building and promotion

Bearing load capacity is determined by the bearing's dynamic load rating, which is the maximum load a bearing can withstand while rotating

This rating is determined by the bearing's size, type, and construction

The dynamic load rating is usually expressed in kilograms or pounds

Other factors that can affect bearing load capacity include the bearing's operating temperature, lubrication, and speed

13.How do you determine the necessary lubrication for a 6010N FAG bearings?

The necessary lubrication for a bearing depends on the type of bearing, the operating environment, and the load it is carrying

Generally, the lubricant should be selected based on the bearing manufacturer's recommendations

Factors such as temperature, speed, and load should also be taken into consideration when selecting the lubricant

Additionally, the lubricant should be compatible with the bearing material and the operating environment

Tag:2305K FAG,NU1048 FAG,2212 FAG,B71938C-2RZ FAG,54320U FAG

Free Delivery

Orders from 70,00 Euro will be shipped free of charge within Germany and to Austria with GLS! Up to 69,99 Euro order volume we charge only 3,90 Euro with GLS. For shipment with DHL GoGreen within Germany we charge only 5,90 Euro up to 69,99 Euro order volume or 2,00 Euro for orders from 70,00 Euro.

Delivery Time: Ready for Shipping within 24h

We try hard to make as much orders as possible ready for shipping within 24 hours (after receiption of payment), because we generally offer only items in our online shop which we have currently on stock. The independent official seal for excellence in shipment always shows you, have fast we are currently working (make your order ready for pick-up by our logistics partner).

Delivery areas:

We deliver to the following countries: Germany, Austria, Switzerland and Belgium, Bulgaria, Denmark, Estonia, Finland, France, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Liechtenstein, Luxembourg, Netherlands, Norway, Poland, Portugal, Romania, Russia, Sweden, Switzerland, Slovakia, Slovenia, Spain, Czech Republic, Hungary, USA. Please find information about delivery costs below. We usually do, but currently do NOT ship to: UK and Norway. Please visit this site frequently for updates or contact our customer service.

Returns

If a product does not meet your expectation for any reason, you can return the product without ifs and buts. To make it even more easy for you, we recommend to use the attached return form and the return stickers free of charge within 30 days of receipt. Just drop the parcel at your nearest GLS parcel shop or DHL branch (depending on the provided return label) in Germany. Of course this is not a compulsory requirement to exercise your right of withdrawal. Find more information on our website for your right of withdrawal.

SKF Bearing

SKF Bearing NSK Bearing

NSK Bearing FAG Bearing

FAG Bearing TIMKEN Bearing

TIMKEN Bearing INA Bearing

INA Bearing NTN Bearing

NTN Bearing